Wholesale China Zinc Alloy Factory Quotes – Aluminum Die Casting Manufacturing Process – GZ Detail:

The company produces CNC machining parts, CNC turning parts, stamping parts, sheet metal, sheet metal chassis, hinges, automotive hardware fittings, medical hardware fittings, health care hardware fittings, furniture hardware fittings, etc.. The company enjoys a high status among hardware trade merchants and furniture supplies, and has established long-term and stable cooperative relations with many wholesalers and agents.

Precision metal stamping, a variety of materials to choose from, precision stamping custom processing

Materials

Genuine 304 stainless steel is used to extend the life of the product.

Appearance

Designed by a senior designer. Details reflect taste! This is also true of industrial product design.

Corners

The corners are designed to be a delight to the eye.

Tactility

Mirror-like smoothness that you can’t help but love

Products from Guanzhi Hardware

We use the finest raw materials to produce products that are beautifully detailed, smooth and rounded to the touch and have a long service life.

Quality Control Process

The whole process is controlled and managed in 16 steps to ensure that the production plant, environment and production equipment meet all requirements. All production processes are carried out in accordance with the approved process plan, checked and upgraded based on experience and proven to meet quality requirements and industry standard production specifications.

Product parameter

| Material | zinc alloy |

| color | Chrome |

| Surface treatment | electroplating |

| Product application | bathroom |

| Weight | 358g |

| Using die-casting machine | 160T |

| Quality | high grade |

| Casting process | high pressure die casting |

| Drawing format | |

| Secondary processing | machining/polishing/plating |

| Main features | bright/corrosion resistant |

| Certification | |

| Test | Salt Spray/Quench |

Our advantage

1. In-house mold design and manufacturing

2. Possess mold, die-casting, machining, polishing and electroplating workshops

3. Advanced equipment and excellent R&D team

4. Various ODM+OEM product range

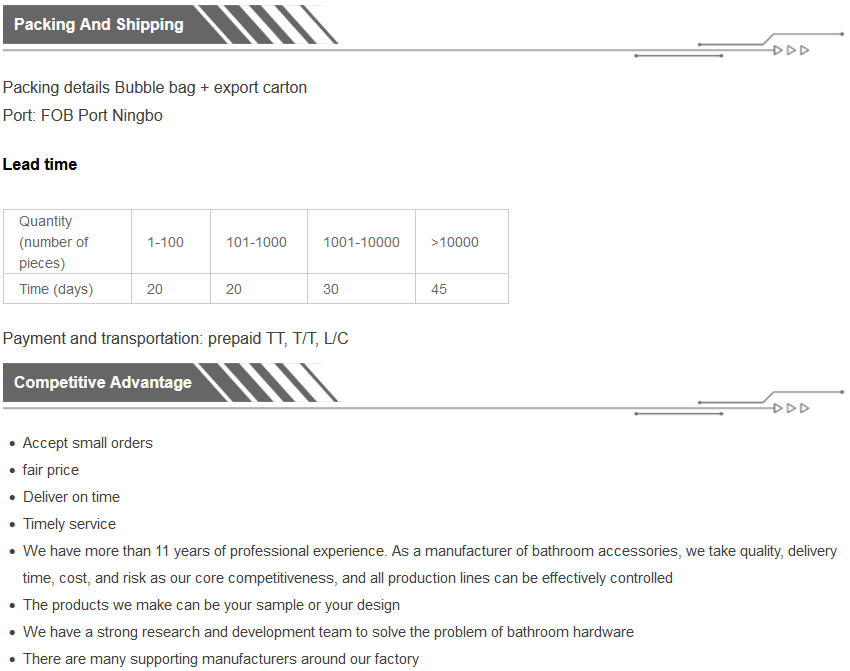

Supply Ability: 10,000 pieces per month

Production process: drawing → mold → die casting-deburring → drilling → tapping → CNC machining → quality inspection → polishing → surface treatment → assembly → quality inspection → packaging

Application: bathroom accessories

Product detail pictures:

Related Product Guide:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Wholesale China Zinc Alloy Factory Quotes – Aluminum Die Casting Manufacturing Process – GZ, The product will supply to all over the world, such as: Greece, Salt Lake City, Panama, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products !

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

-

Wholesale China Aluminum Cans Crafts Factory Qu...

-

Wholesale China Aluminum Art Case Manufacturers...

-

Wholesale China Aluminum Die Cast Cylinder Head...

-

Wholesale China Aluminum Motorcycle Cylinder He...

-

Wholesale China Zinc Alloy Button Factory Quote...

-

Wholesale China Cupc Faucet Factory Quotes R...