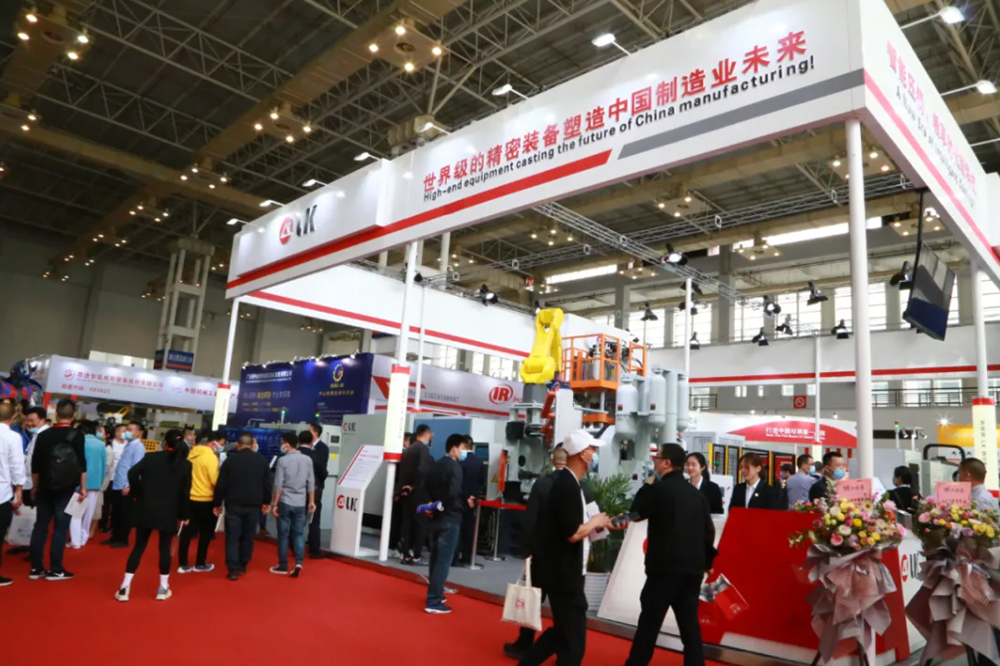

2021 Ningbo Foundry, Forging and Die Casting Industry exhibition.

From April 22nd to 24th, the 12th (2021) Ningbo Foundry, Forging and Die Casting Industry Exhibition was held in Ningbo International Convention and Exhibition Center.

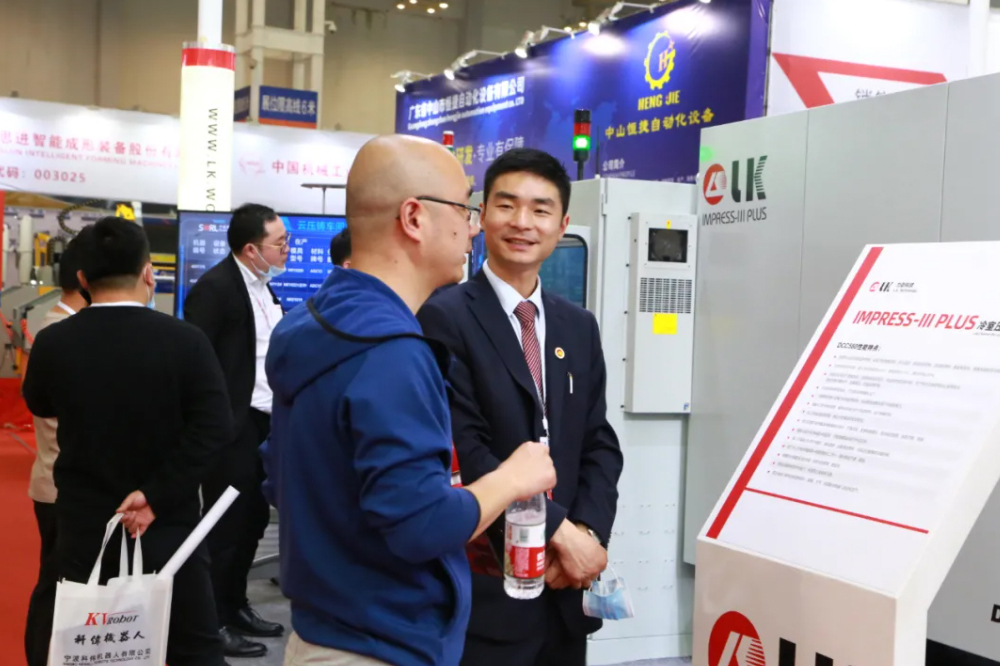

At the 3A201 booth, Lijin IMPRESS-PLUS DCC580 intelligent cold chamber die-casting unit, AVIS-ⅡDC50 hot-chamber die-casting machine, and TC-1000 high-speed drilling and milling machining center were exhibited.

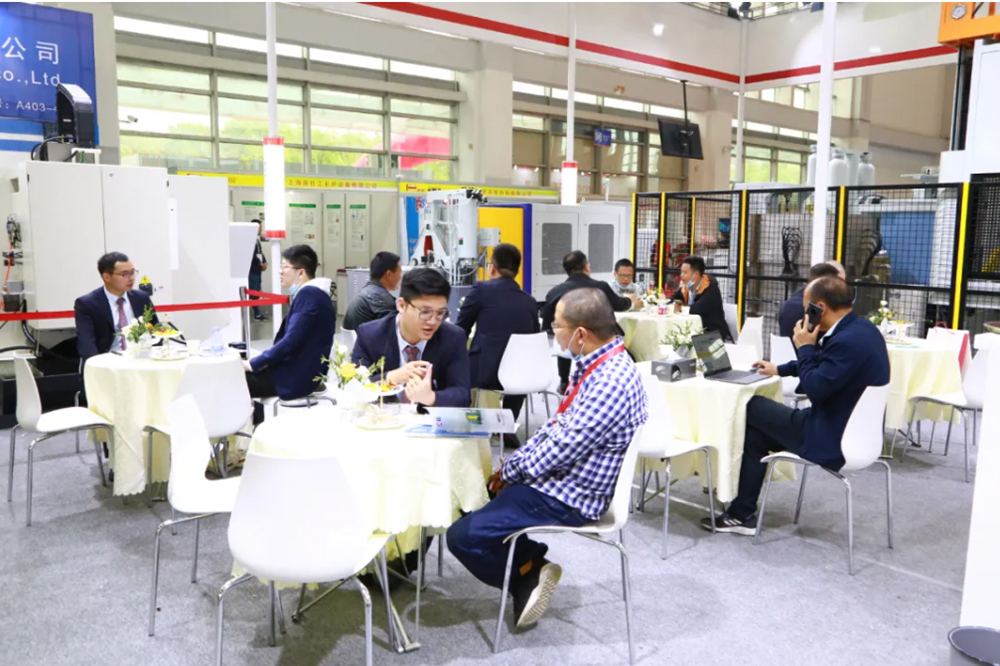

On-site demonstration of Lijinyun die-casting solutions, showcasing new energy vehicles, 5G communications and other emerging industries to build an industrial 4.0 cloud die-casting intelligent production system, high-efficiency, high-precision die-casting drilling and tapping automated processing solutions.

Intelligent cloud die casting production solution

IMPRESS-PLUS DCC580 intelligent cold chamber die-casting unit combines the actual production experience of many customers at home and abroad, and integrates into the advanced cloud die-casting smart factory management system. It has excellent injection performance, simple operation, easy to use and easy to use.

It has a new PLC real-time control injection system, workshop production management system, intelligent mold opening and locking system and intelligent mold adjustment, accurate remote network monitoring, intelligent judgment, intelligent feedback, cloud storage and other functions to realize intelligent die-casting production.

Intelligent production solutions for zinc alloy products

The AVIS-Ⅱ DC50 hot chamber die casting machine inherits the design advantages and mature technology genes of the Lijin hot chamber die casting machine, meets the production needs of zinc alloy products, combines the practical application experience of many die casting enterprises and customers, and incorporates new technologies, new processes, and new concepts , Improve performance, quality and efficiency.

Intelligent and easy-to-operate design, excellent oil pressure system, high-performance pressure and flow control, energy saving and environmental protection. Equipped with automated peripheral equipment to realize intelligent production.

Drilling and tapping solutions for large structural parts

TC-1000 high-speed drilling and milling machining center is a large-scale vertical drilling and milling machining center newly developed by Lijin Group. It has high rotation speed, high displacement speed, larger table size and load, X/Y axis travel and spindle torque. Better spindle rigidity makes up for the weak torque of traditional drilling and tapping center spindles.

Meet the needs of high-speed and high-efficiency machining of large-size workpieces. The post-processing of non-ferrous metals, especially aluminum alloy die-casting parts, such as new energy vehicle body structures, battery shells, communication transmitter shells, filter shells, etc., has high-efficiency and high-precision processing performance.

From a digital enterprise to an Industry 4.0 smart factory, Lijin Group deeply integrates industrial software technology, automated die-casting technology and lean manufacturing to achieve intelligent production and high flexibility, low cost, high quality and high efficiency to meet the individual needs of customers.

Post time: Jul-23-2021